Concern & action: Installation quality

Product/material requires a standard of quality installation in order to operate as intended

Suggested actions

Before Implementation

Define installation quality requirements e.g : use only system trained and approved installers for measure and put in place on site quality checking procedures, monitoring and/or testing (e.g. thermographic survey of cavity wall infill). Ensure design and supply chain are aware of critical aspect of installation quality for success of measure. Provide information so that it can be understood by a range of people - from the well informed expert to the complete novice. Consider using a supply contract that guarantees quality and performance, which requires supplier to put right any failure due to poor installation. If quality of installation cannot be guaranteed consider alternative product.

During implementation

Carry out on site checks to confirm quality of installation. Report any discrepancies with requirements and amend as necessary.

After implementation

Feedback any installation problems encountered to manufacturers, suppliers and specifiers

RELATED MEASURES

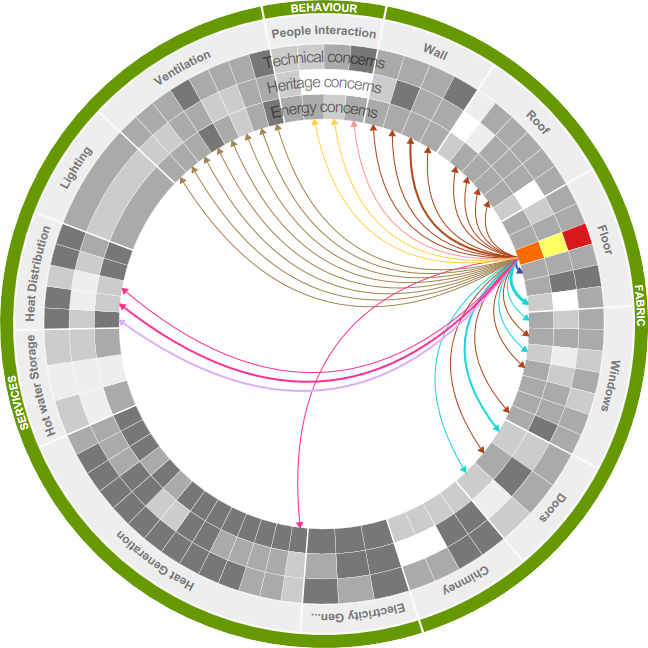

FABRIC (21)

FABRIC (21)

External Wall insulation

Internal Wall insulation

Frame infill insulation

Loft Hatch insulation

Loft insulation

Rafter insulation

Flat roof insulation

Room in roof insulation

Loft hatch and ceiling airtightness

Floor insulation between/under floor joists

Floor Insulation on top of existing floor finish

Floor void filled with insulation

Exposed soffits to upper floors: Insulation in between joists or under soffit

Replacement of existing ground floor with new concrete insulated solid ground floor

Increased Floor airtightness

Window draughtproofing

Secondary glazing

Window External Shading

Window Replacement

High performance doors

SERVICES (18)

SERVICES (18)

High efficiency gas-fired condensing boilers

Oil-fired condensing boilers

Air source heat pumps

Ground/Water source heat pumps

Biomass boilers

Biomass stove with back boiler

Solar water heating

Communal heat generating system

Micro combined heat and power

High efficiency replacement warm-air units

Pipe insulation

Wet Under-floor heating

Communal Heat Distribution System and controls

Continuous mechanical extract ventilation

Continuous mechanical supply and extract ventilation with heat recovery

Continuous mechanical extract ventilation with demand control ventilation

Continuous mechanical supply and extract ventilation with heat recovery and with demand control ventilation

BEHAVIOUR (1)

BEHAVIOUR (1)

RELATED REFERENCES (16)

Double Glazing in Listed Buildings – Project Report (2010)

Heath, N

Energy efficiency And Historic Buildings: Open fires, chimneys and flues (2012)

English Heritage

The Impact of energy efficient refurbishment on the airtightness in English dwellings (2006)

Hong,S., Ridley, I., Oreszcyn, T., and the Warm Front Study Group

Energy Efficiency In Historic Buildings - Draught-proofing windows and doors (2010)

English Heritage

Energy Efficiency In Historic Buildings -Secondary glazing for windows (2010)

English Heritage

Here comes the sun: a field trial of solar water heating systems (2011)

Energy Saving Trust

Future Fit: Installation Phase in depth findings (2011)

EST/Affinity Sutton

The usability of control interfaces in low-carbon housing, Architectural Science Review, 56:1, 70-82 ( 2013)

Stevenson F, Carmona-Andreu I and Hancock M

Renewable Heritage: A guide to microgeneration in traditional and historic homes (2009)

Changeworks

Detailed analysis from the first phase of the Energy Saving Trust’s heat pump trial (2012 )

Dunbabin P and Wickins C

Micro CHP Accelerator - final report (CTC788) (2011)

Guy,R. and Sykes,B.

Assessing the execution of retrofitted external wall insulation for pre-1919 dwellings in Swansea (UK) (2010)

Hopper, J., Littlewood, J., Geens, A., Karani, G.,Counsell, J., Evans, N. and Thomas, A.

BRE IP 4/06 Airtightness of ceilings - Energy loss and condensation risk (2006)

Sanders C, Haig J, Rideout N

Early cavity walls (2012)

English Heritage

Getting Warmer: a field trial of heat pumps (2010)

Energy Saving Trust

Energy-led retrofitting of solid wall dwellings: technical and user perspectives on airtightness. Structural Survey, 30 (3), pp. 267 - 279 (2012)

Banfill P, Simpson S, Haines V, Mallaband B